"We Don't Just Fix Problems - We Build Solutions"

WELCOME TO OUR BOILER SHOP

The VCX-O2 Oxygen Analyzer System is an oxygen analyzer system designed for use with the Fireye NXCESO2 In-situ probe. The electronics unit is based on a compact 7” HMI touchscreen & PLC combination, for use with the industry proven, industrial grade zirconium dioxide, dual cell sensor probe from Fireye Inc. Designed as a standalone system, the VCX-O2 brings the safety of a low oxygen shutdown to boilers with single-point positioning systems, as well as an economical O2 analyzer alternative for parallel positioning systems such as the Hays Cleveland UPAC and Cleaver-Brooks Hawk. The VCX-O2 provides power and communication to the oxygen probe thru a 4-wire cable connection. While the Oxygen probe is designed to mount in the stack, the VCXO2 is designed for remoted mounting close to the boiler and or existing control panel.

The VCX-O2 Oxygen Analyzer System is an oxygen analyzer system designed for use with the Fireye NXCESO2 In-situ probe. The electronics unit is based on a compact 7” HMI touchscreen & PLC combination, for use with the industry proven, industrial grade zirconium dioxide, dual cell sensor probe from Fireye Inc. Designed as a standalone system, the VCX-O2 brings the safety of a low oxygen shutdown to boilers with single-point positioning systems, as well as an economical O2 analyzer alternative for parallel positioning systems such as the Hays Cleveland UPAC and Cleaver-Brooks Hawk. The VCX-O2 provides power and communication to the oxygen probe thru a 4-wire cable connection. While the Oxygen probe is designed to mount in the stack, the VCXO2 is designed for remoted mounting close to the boiler and or existing control panel.

The VCX-500 is a remote monitoring system for use with mobile and rental boilers. This system is for mounting in the boiler control room, to provide the facility operators visual

The VCX-500 is a remote monitoring system for use with mobile and rental boilers. This system is for mounting in the boiler control room, to provide the facility operators visual

indication of the state of the rental/mobile boiler.

The VCX-500 Remote Monitoring System utilizes a standard

4-20mAdc signal for boiler pressure indication, and standard

Modbus RTU communications to the Flame Safeguard

system. Designed use on rental/mobile boilers where the operator

needs to know the status of the boiler but cannot leave the control room or boiler plant floor unless there is an emergency, the VCX-500 fills that need.

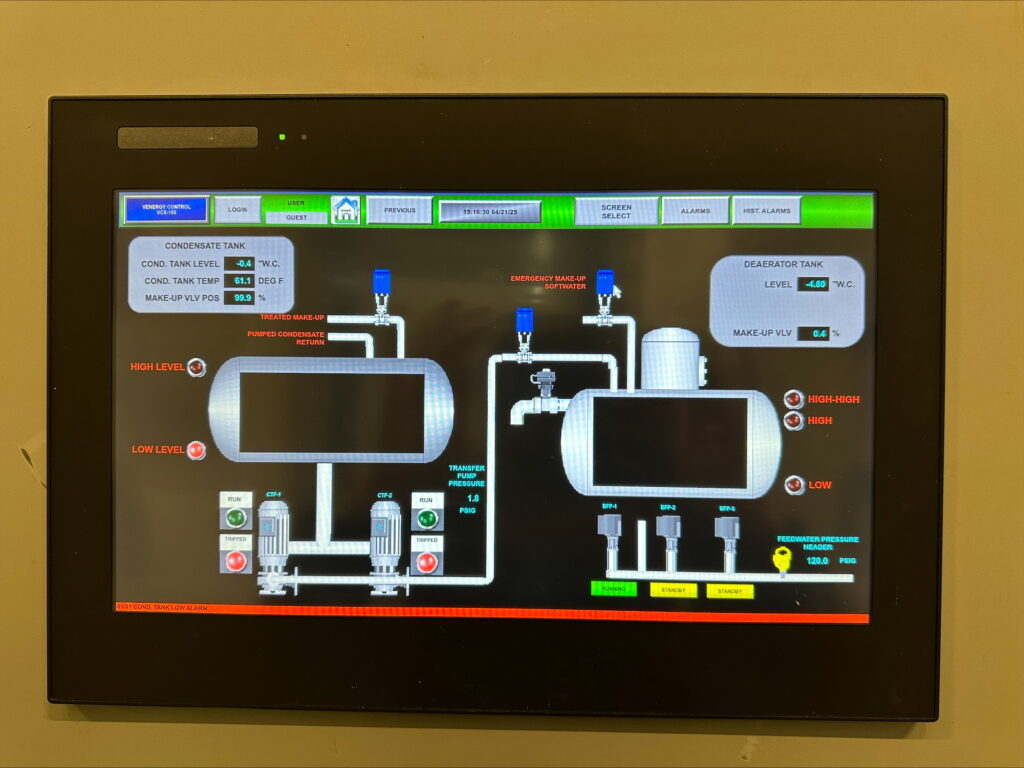

TVCX-100 Boiler Plant Feedwater Control system, based on the industry proven Hays Cleveland UPAC™ control platform and under a Hays Cleveland/Venergy Group mutual

TVCX-100 Boiler Plant Feedwater Control system, based on the industry proven Hays Cleveland UPAC™ control platform and under a Hays Cleveland/Venergy Group mutual

agreement, represents the ultimate in boiler plant feed water

control systems. The VCX’s modular approach provides almost unlimited capability. Main components include a touch screen, control unit and expansion modules for analog and digital I/O.

Designed to meet the stringent master specifications of the

Department of Veterans Affairs, the VCX-100 meets the Department of VA master specification section 23 09 11 and 23 50 11. In addition, the VCX-100 is considered to be the ultimate in safety and reliability for any industrial or

commercial installation. As a complete solution, the VCX Series is flexible, and easily field configurable to meet the most common installation requirements, simply by the start-up technician enabling and/or disabling the various built-in options. Combined with the VCX-1000 Boiler Controls, and VCX-2000 Plant Plant Master Control, The VCX Series Control System meets the Master VA Specification Requirements of all controllers to be same make and model per specification 23 09 11, pp 2.2. And 23 50 11 pp’s 2.2.S.3 & 2.3.L.4.

The VCX-LOOV has been custom engineered to provide a solution for the Department of VA requirement for “Lock Open-Only” valves to be installed on their

The VCX-LOOV has been custom engineered to provide a solution for the Department of VA requirement for “Lock Open-Only” valves to be installed on their

boiler safety devices.

The VHA Safety Device manual calls for valves on the safety devices to be lockable in the open position only, and must be done so without physically modifying the

valve by cutting off a tab or stop. We developed a custom block that is mounted to the valve using the threaded mounting holes built into the valve, and secured it with one way security screws so it cannot be removed once fitted. This is not considered a physical

modification to the valve, but is an enhancement utilizing existing features of the valve.

MORE ON BOILERS

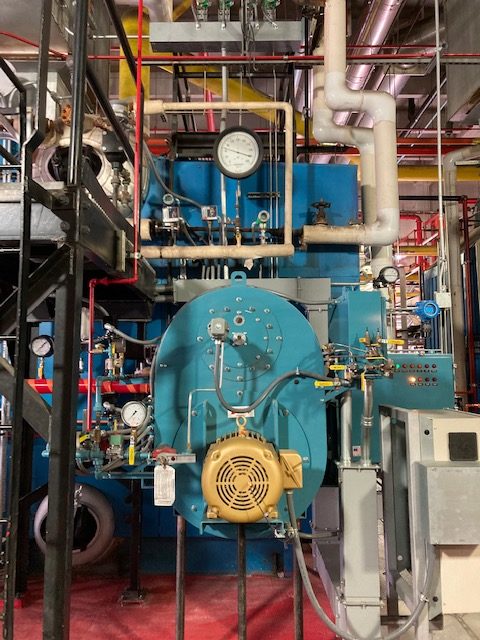

The Boiler Division of Venergy specializes in the testing, inspection and maintenance of all boiler and burner systems along with its ancillary equipment in accordance with ASME and National Board codes, Local Jurisdictions and Authorized Inspectors requirements, Original Equipment Manufactures’ Instructions, and all VA directives including VA1810D and the VA Safety Device Testing Manual (8th Edition).

LOOKING TO GET IN TOUCH?

John FRY

Project Manager / Boiler Shop Manager

Contact Form

VIEW our work BELOW!